Expand Your Knowledge

Our resource center archives our case studies, published articles, blogs, webinars, and image galleries. Discover ways microscopy has made a meaningful impact.

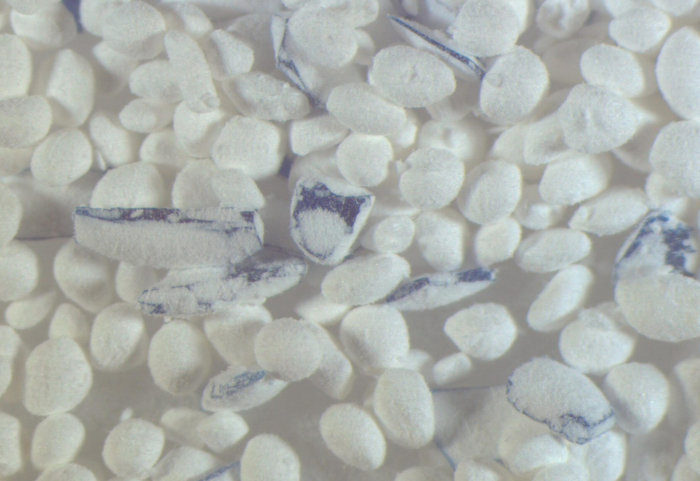

Recalls can occur due to the presence of foreign particulate in pharmaceutical products. This situation can be dangerous as particulate in injectable drugs can enter the bloodstream. In oral medications, particulate could cause damage to teeth or internal organs if they are digested. Particulate may also affect the drug’s potency. Therefore, pharmaceutical companies have to make sure that their products are free of unwanted particulate. This is typically done through a process called visual inspection.

There are three types of visible particles that may be found during a visual inspection: extrinsic, intrinsic, and inherent. Extrinsic particulate is not part of the product or the manufacturing process and can be materials such as hair, fiber, or metal. Intrinsic particulate is part of the product or the packaging; often the source is known, and these can include materials such as glass or rubber. Inherent particulate is the result of aggregation or crystallization of active pharmaceutical ingredients (API) or the excipients.

MVA Scientific Consultants is an FDA registered, DEA approved, and cGMP compliant analytical service lab. MVA provides microscopy, spectroscopy and litigation support for pharmaceutical and medical device companies; we specialize in foreign particulate identification, particle shape and size distribution analysis, drug polymorph characterization and morphology studies, nonconformance and root cause analysis, component distribution mapping, and delamination/corrosion studies.

We can provide ongoing analytical support for all phases of drug development: the discovery phase, preclinical and clinical research, Food and Drug Administration (FDA) review, and post-marketing. We help manufacturers verify that their products meet the FDA’s specifications and guidelines to avoid and manage recalls. In the case of a product recall due to foreign particulate, MVA provides timely and reliable service support to help manufacturers identify the foreign particulate and determine the source of the contamination. Taking such preventive actions helps the manufacturers avoid a bigger loss of time and money and can help alleviate any regulatory concerns.

Glass vial delamination/corrosion has resulted in an increasing number of recalls. Our scientists have developed a protocol for preparation and examination of glass vials for assessing the interaction of the drug product with the glass. The analysis involves filtering the drug product, examining the filter for glass lamellae, and inspecting the vial’s interior surface for corrosion. The insights gained from the results can help the manufacturer take preemptive action early in the delamination/corrosion process.

For more information about our services, call us at 770-662-8509 or email us at info@mvainc.com.