Expand Your Knowledge

Our resource center archives our case studies, published articles, blogs, webinars, and image galleries. Discover ways microscopy has made a meaningful impact.

Manufacturers encounter various issues during production processes that could upset their manufacturing timeline. Faulty or substitute raw materials, contaminants in final products, coating and adhesion failures, surface defects, corrosion, and discoloration can all adversely affect the final product. Product failure can occur due to product design, the manufacturing process, product packaging or storage, and/or misuse of the product.

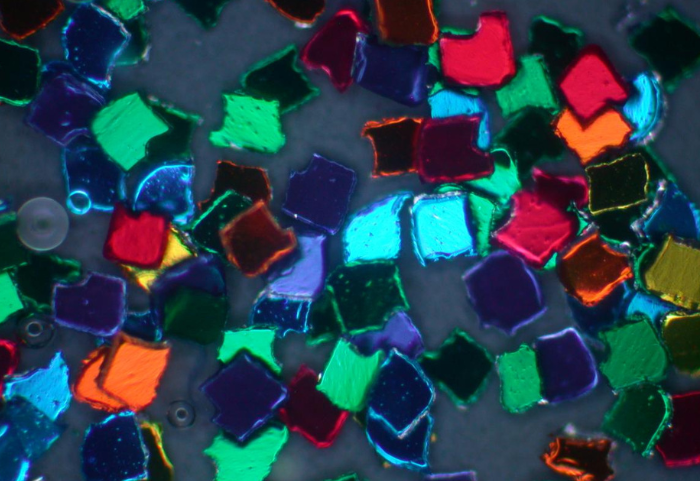

MVA Scientific Consultants has over 35 years of experience in working with manufacturing facilities’ research & development, quality, packaging and customer return departments. We have worked with a range of materials including composites, metals, glass, plastic, polymers, ceramics, packaging, coatings, and paint. Our experience spans many different industries including personal care products, printing, electronics, medical, and aerospace.

Failure analysis is an important tool in determining the root cause of failures, preventing similar product failures in the future, and improving manufacturing processes and products. It can also help to eliminate any physically harmful effects from defective products and reduce financial costs. We help companies characterize contaminants, analyze product failures, investigate packaging failure, etc.

We also help manufacturers with adhesive, coating or paint failures. These failures occur at the interface between the adhesive/paint film and the adherent or coated surface. These failures can be caused by fluid, heat, and materials that are present in the interface, changes to the adhesive or changes to the adherent surface. By identifying the cause of the failure, actions can be taken to prevent it from occurring again.

Plastic failure can manifest in several ways: contamination, fractures, discoloration, distortion and degradation. Due to the variation in plastic composition, characterizing the failure and identifying the cause can be complicated. Failure testing of plastics requires expertise and specialized testing to fit the product.

We also provide failure analysis to the pharmaceutical and medical devices industry. Medical device failure has serious consequences. Failure can be in the form of breakage, corrosion or contamination. If contamination has been detected in a product, it is essential for manufacturers to identify it quickly in order to prevent similar incidents. Our failure analysis process depends on the product, type of failure, and our clients’ inquiries. We pride ourselves in providing valuable, customized, independent analysis in a timely and reliable fashion while using cutting edge techniques.

Contact us regarding a product failure, call us at 770-662-8509 or email us at info@mvainc.com.