Expand Your Knowledge

Our resource center archives our case studies, published articles, blogs, webinars, and image galleries. Discover ways microscopy has made a meaningful impact.

Surface measurement, also known as surface metrology, refers to the measurement of topography or surface roughness of precision surfaces. Surface roughness and the details of the surface profile determine the performance and appearance of many products. The roughness or texture of a part is important for a surface’s suitability in different applications.

Component failures are often related to a precision surface that was not manufactured to specification, either due to an improperly set up machine or use of a process that is not capable of reproducing the quality of surface needed.

Surface analysis by white light interferometry is well-suited to address numerous applications. Common sample types include moldings, automobile parts, electronics, leathers, papers, failed components, medical devices and solar panels. Accommodating many sample geometries, our surface topography characterization lab offers an array of possible dimension analyses and a versatile Z-range.

Examples of MVA’s surface measurement projects include:

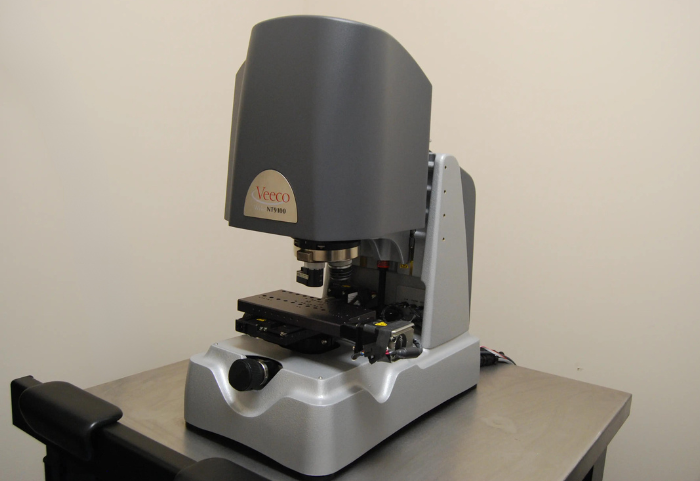

Scanning white light interference microscopy (SWLIM) is a non-contact optical profilometry technique used to obtain three-dimensional images and quantitative measurement of surface texture or “roughness.” The technique requires minimal sample preparation, is non-destructive, extremely fast, and able to analyze a variety of sample types. Sampling of large areas is possible with the motorized and automated sample stage. Measurements include surface shape, surface finish, surface profile roughness (Ra), surface texture, and structural characterization.

Typical roughness statistics calculated for each surface include:

In addition to the interferometry method, MVA Scientific Consultants also has two scanning electron microscopes (SEM) that can provide high resolution surface imaging. SEM is a very powerful technique for surface analysis. It is a non-destructive technique and provides extremely high magnification. It can achieve a lateral resolution in the nanometer range. When coupled to an energy dispersive x-ray (EDS) system, the SEM can also obtain surface elemental composition of a sample.

Contact us for your next project. Email info@mvainc.com or give us a call 770-662-8509.

Click the thumbnail to view the full image in a new page.