Optical Profilometry Surface Measurement

Surface measurement, also known as surface metrology – refers to the measurement of topography or surface roughness of precision surfaces. Surface roughness and the details of the surface profile determine the performance and appearance of many products. The roughness or texture of a part is important for a surface’s suitability in different applications.

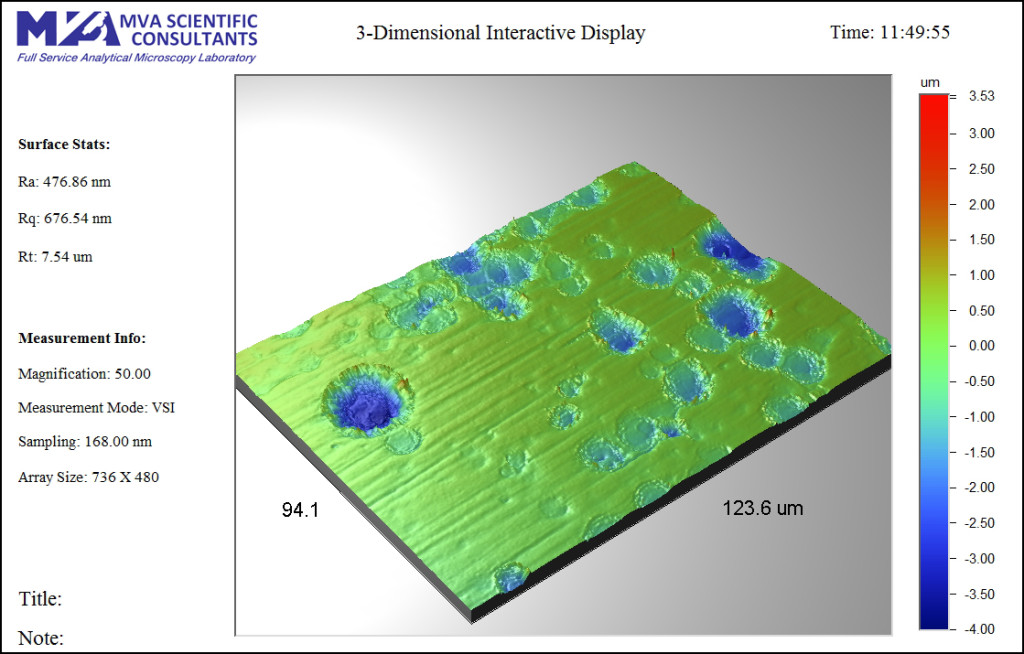

Component failures are often related to a precision surface that was not manufactured to specification, either due to an improperly set up machine or use of a process that is not capable of reproducing the quality of surface needed.

Surface Measurement System Features

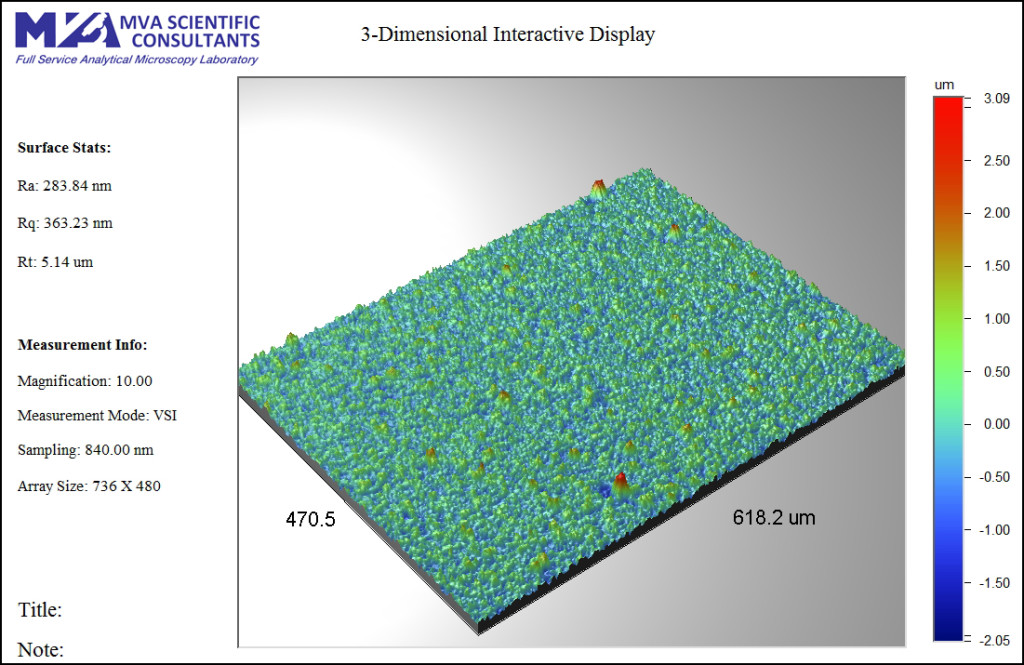

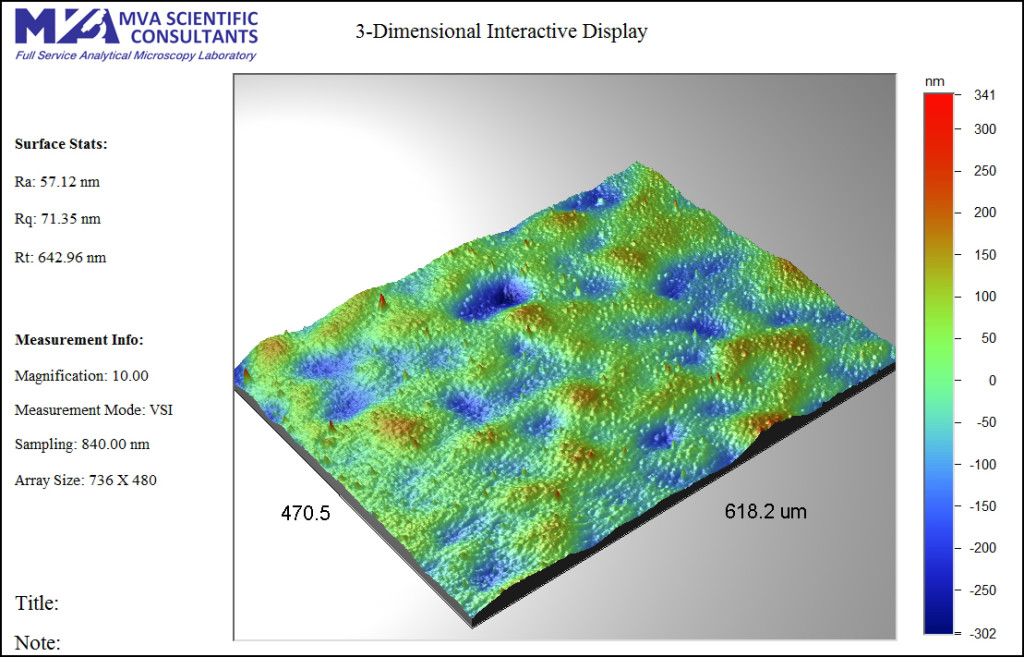

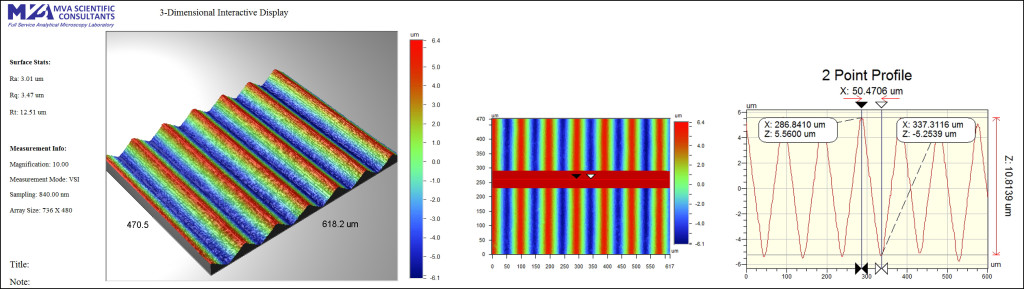

Scanning white light interference microscopy is a non-contact optical profilometry technique used to obtain three-dimensional images and quantitative measurement of surface texture or “roughness.” The technique requires minimal sample preparation, is non-destructive, extremely fast and able to analyze a variety of sample types. Measurements include surface shape, surface finish, surface profile roughness (Ra), surface texture, and structural characterization.

Typical roughness statistics calculated for each

surface include:

- Ra (average roughness)

- Rq (average root mean square roughness)

- Rt (total roughness)

Examples of MVA’s surface measurement projects include:

- Surface roughness measurement of mechanical parts

- Measurement of coating finishes on parts

- Surface analysis of medical device implants

- Contact molding analysis

- Comparison of solar panels

- Cast member filter

- Polymer surface smoothness

Unlike stylus profilometry and physical cross-sectioning techniques, interference microscopy results in hundreds of sample “cross-sections” without ever touching the sample surface. The data can then be plotted as a three-dimensional representation of the sample surface. Sampling of large areas is possible with the motorized and automated sample stage.

With over 30 years of experience, MVA Scientific Consultants has solved over 11,000 interesting and challenging problems.

Our philosophy has always been to provide clients with the highest quality data that will be valuable in helping them solve their issues.

For more info visit:

Surface Topography Characterization Services

Scanning White Light Interference Microscopy

To learn more about how we can handle your specific analysis and testing needs, contact us at info@mvainc.com or 77-662-8509.